Introduction

This manual provides a step-by-step guide on how to dimension and build a portable solar concentrator, with a detailed breakdown of the components, the tools required.

A high-efficiency solar concentrator capable of reaching temperatures above 300°C developed by volks.eco for plastic recycling, can also be used for solar cooking or any heating activity. This machine offers an eco-friendly solution for various applications.

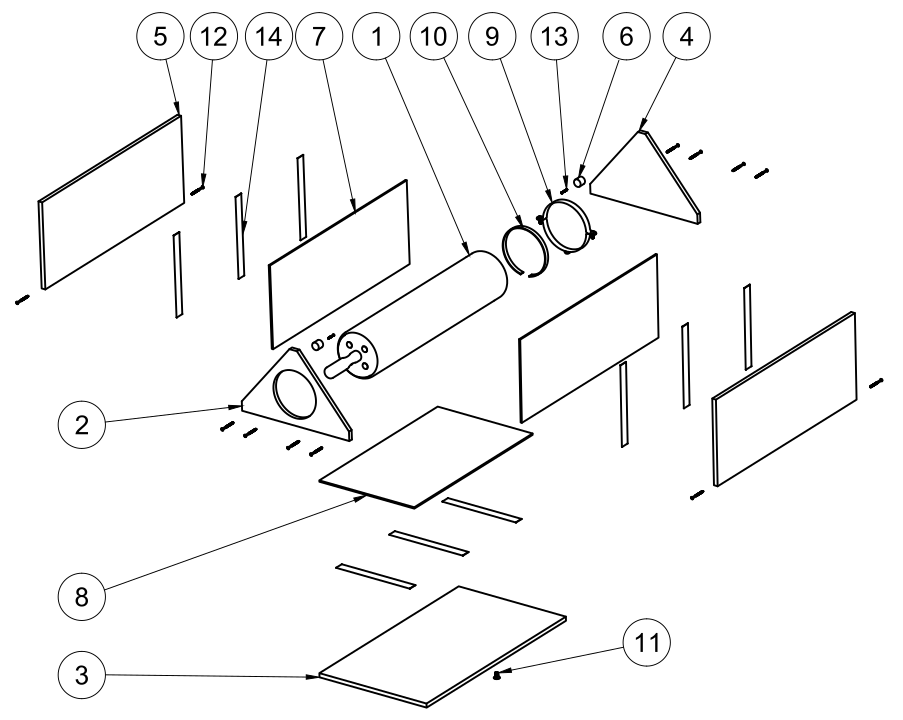

The Components

Must of the components required can be found in the open market and can be made with hand tools :

-

1 x Solar oven vacuum tube (1)

-

1 x Front board (2)

-

1 x Bottom board (3)

-

1 x Backboard(4)

-

2 x Lateral board(5)

-

2 x Bottle stopper(6)

-

2 x Lateral mirror (7)

-

1 x Bottom mirror(8)

-

1 x Clamp D140 mm M8 Fem(9)

-

1 x Cork sheet(10)

-

1 x Screw DIN7991 M8x16mm(11)

-

12 x Wood screw 2"(12)

-

2 x Wood screw 1"(13)

-

9 x Double sticky tape 25mm long(14)

Tools Needed

Miter saw

Tape measure

Star-tip driver

4mm diameter drill bit

8mm diameter drill bit

Creating the Sun Concentrator

DIMENSIONS

To ensure greater effectiveness, the sizing of the concentrator must be adapted to the geographical situation and the maximum sun elevation using the declination angle throughout the winter time at 12h.

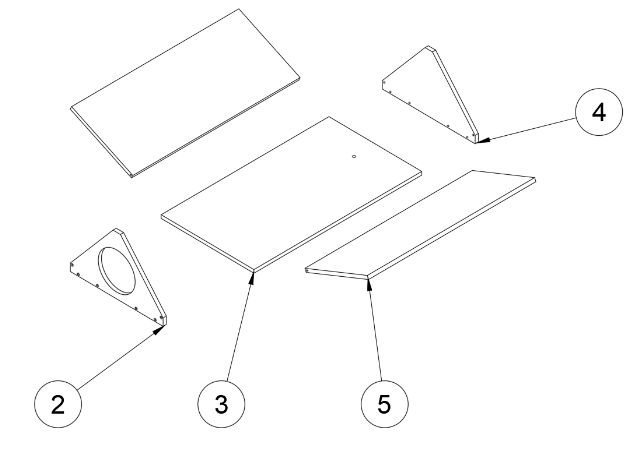

CUTTING THE WOOD

Start by cutting the wooden components to the required dimensions using a miter saw and the 2D plans. It’s also possible to buy precut wood with the external dimensions than finish the shapes and holes home.

The components

-

1 x Front board (2)

-

1 x Bottom board (3)

-

1 x Backboard(4)

-

2 x Lateral board(5)

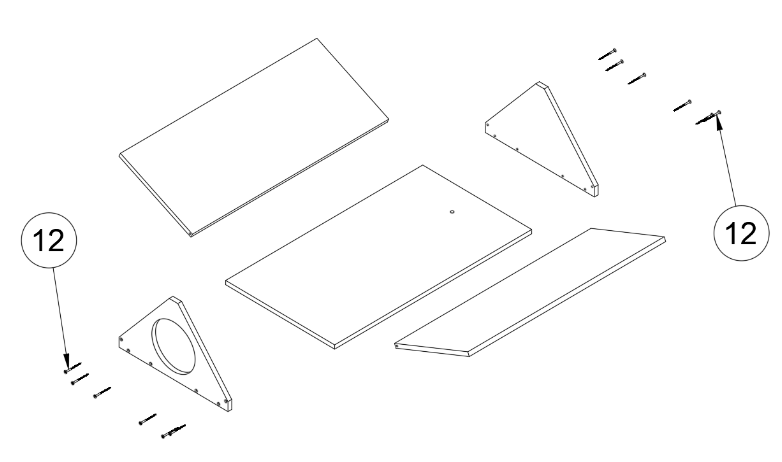

ASSEMBLE THE WOOD FRAME

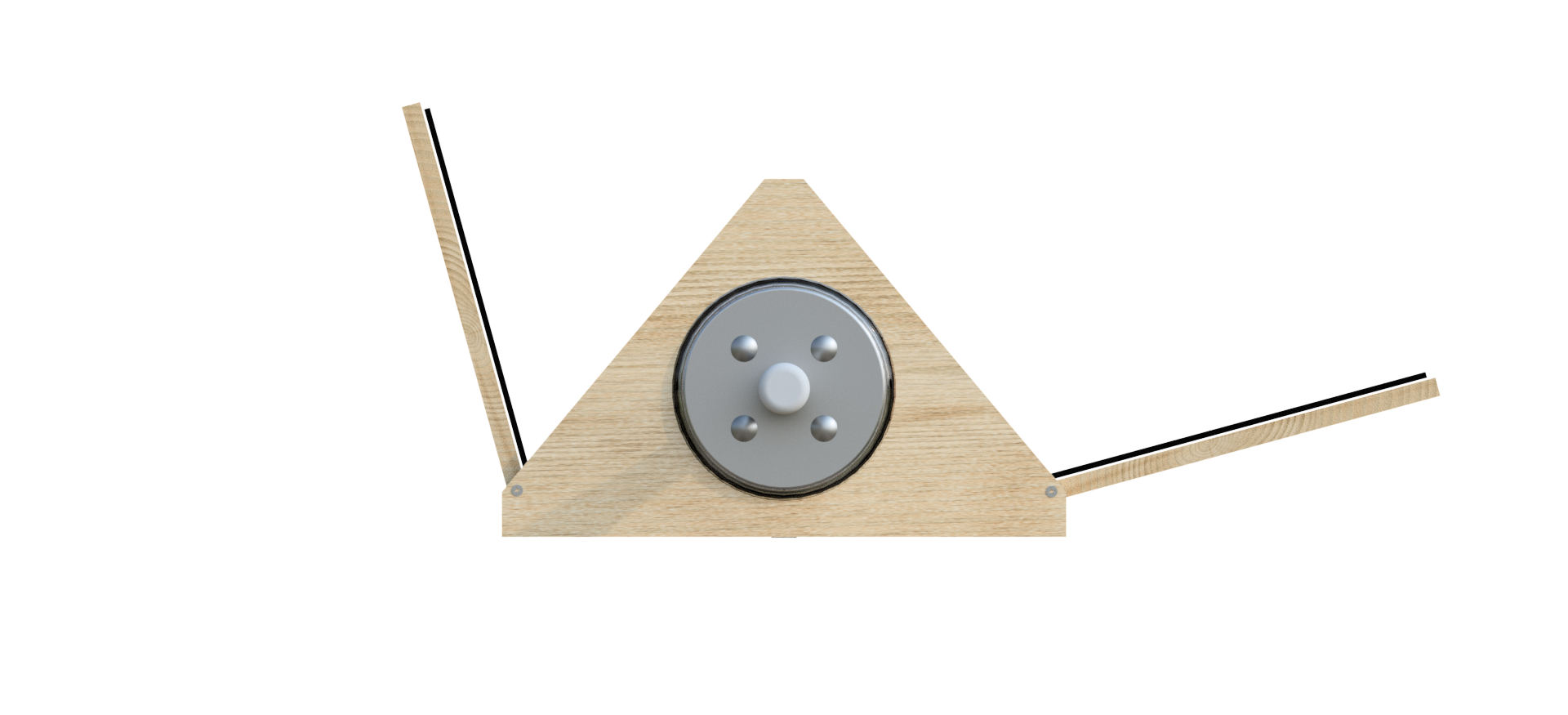

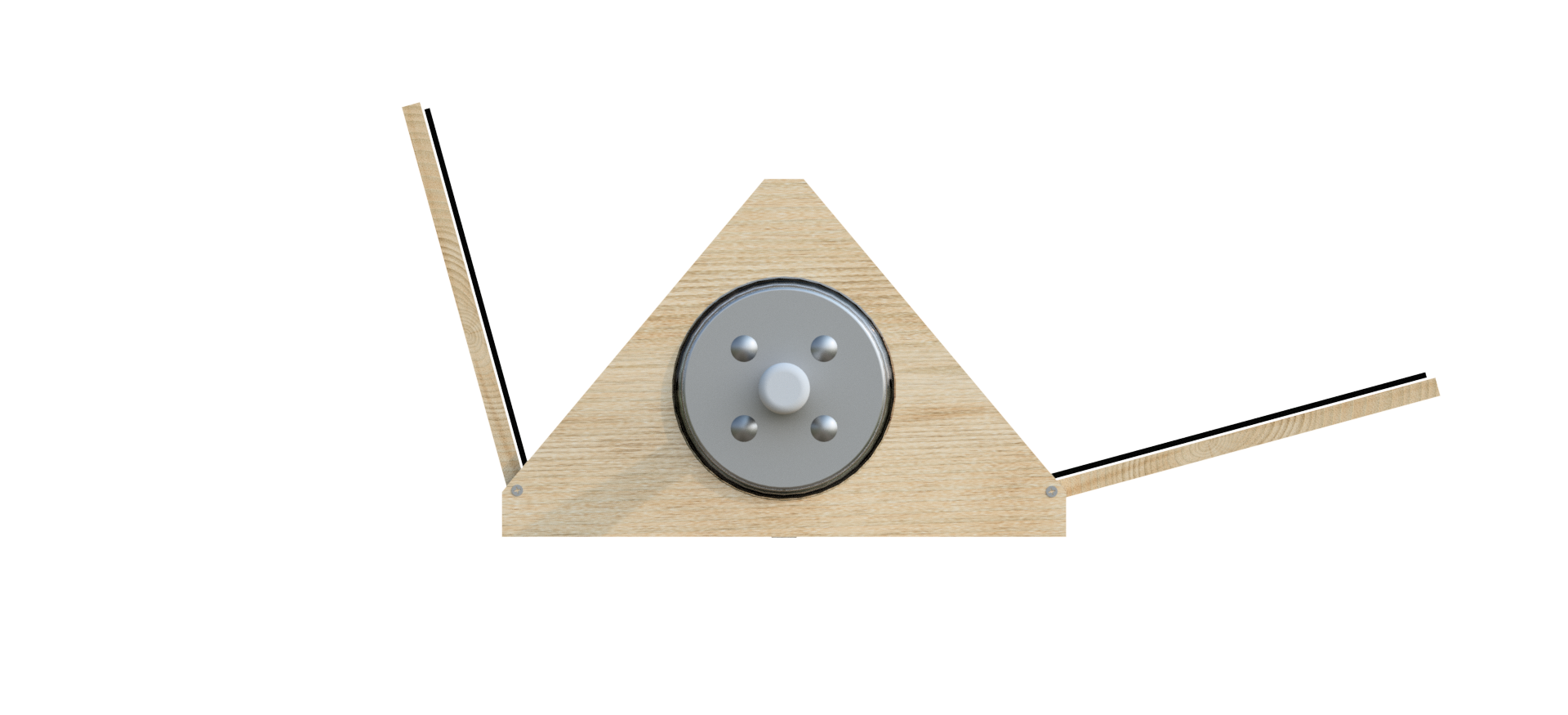

Wooden Frame : A simple wooden frame to support the tube and the mirrors.

The components

-

1 x Front board (2)

-

1 x Bottom board (3)

-

1 x Backboard(4)

-

2 x Lateral board(5)

-

12 x Wood screw 2"(12)

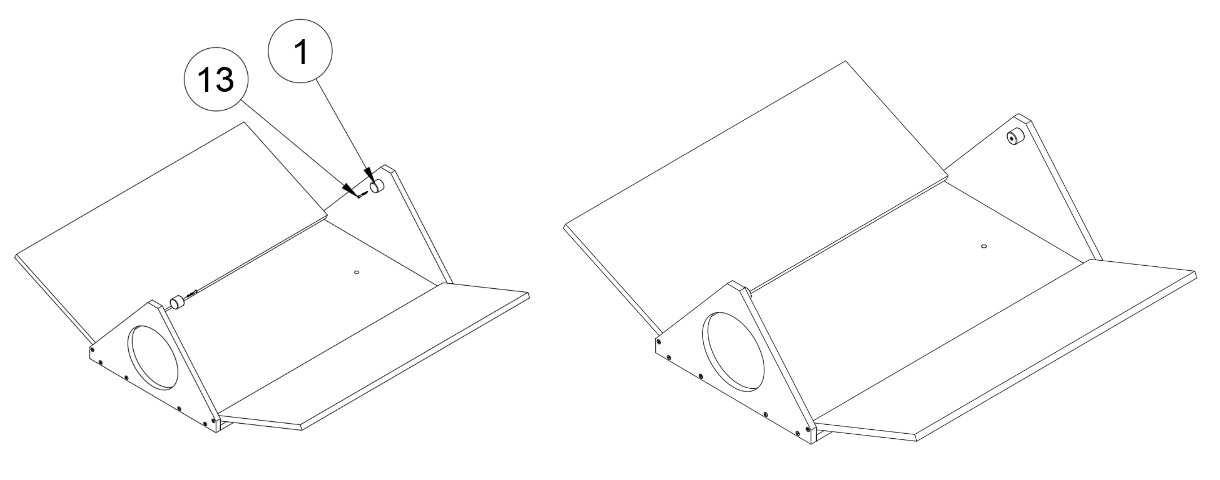

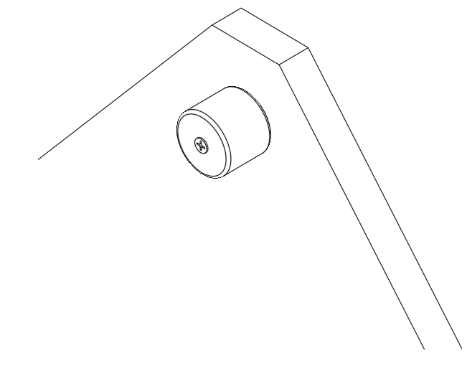

LATERAL STOPPER

The lateral stoppers are made of bottle stoppers and screws. These components are needed to protect the mirrors and close the concentrator.

The components

-

2 x Bottle stopper(1)

-

2 x Wood screw 1"(13)

Cork stopper : Using to stop the mirror lateral supports. (1)

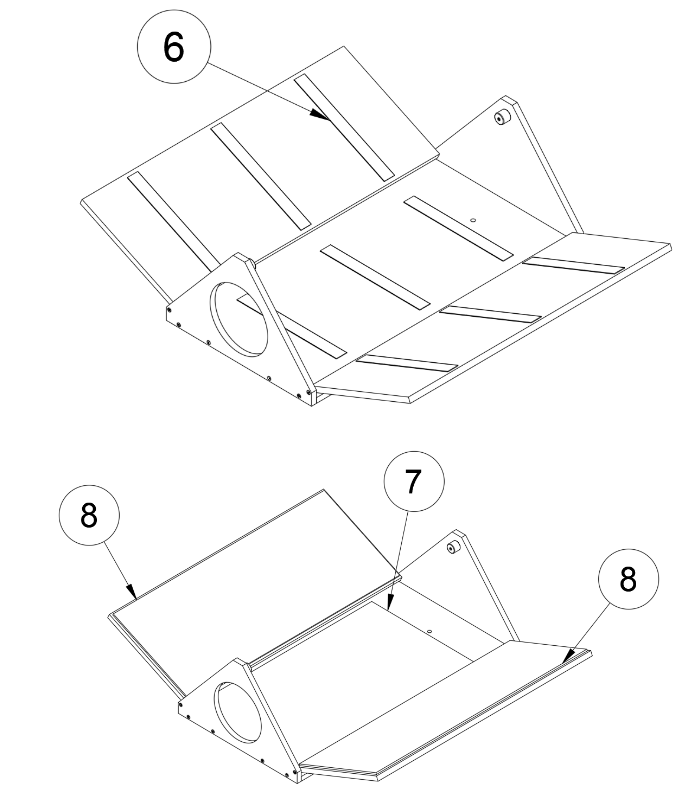

Stick the mirrors

Three mirrors, including two side mirrors and one bottom mirror, focus sunlight onto the solar tube.

The components

-

1 x Bottom mirror(7)

-

2 x Lateral mirror (8)

-

9 x Double sticky tape 25mm long(6)

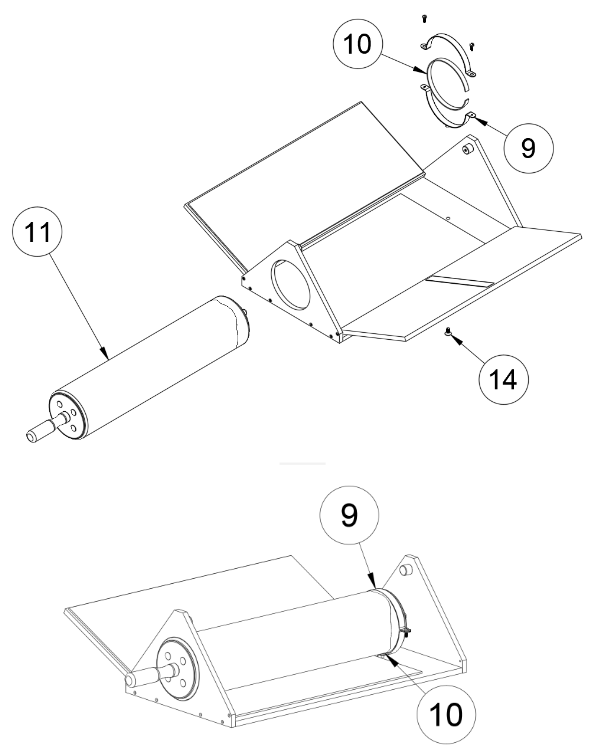

ASSEMBLE THE VACUUM TUBE

Solar Concentration Tube : A vacuum tube that efficiently captures solar thermal energy. (1)

The components

-

1 x Solar oven vacuum tube (11)

-

1 x Clamp D140 mm M8 Fem(9)

-

1 x Cork sheet(10)

-

1 x Screw DIN7991 M8x16mm(14)

Screws, pipe clamps and fasteners to assemble the structure. (9,11,12 & 13)

The cork sheet serves to protect the tube from assembly pressure and absorb the expansion and contraction effects of the glass. (10)

Maintenance

To maintain the concentrator's performance and safety, regularly measure and monitor the temperature to ensure it doesn't exceed 320°C to prevent vaccum tube degradation. Perform regular inspections and adjustments if necessary.

How to Use the Solar Concentrator

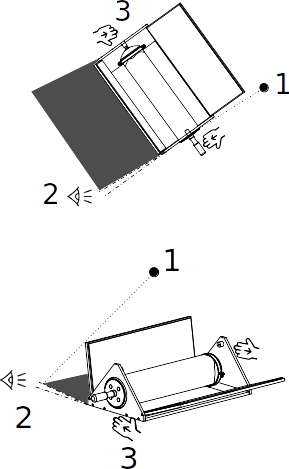

ORIENTATION

Dependent on the geographical situation, the hour, and the time of year. At 12 noon real-time, the sun will be at its highest point facing the south. During use, the concentrator must rotate to remain perpendicular to the sun in the longitudinal direction.

Two methods of using the concentrator exist :

-

Regular orientation to follow the sun's rays permits maximum efficiency and usage at higher temperatures for more hours during the day.

-

Positioning the concentrator pre-oriented towards the south and using it at a specific time with maximum heat.

The azimuth is determined by positioning the laterals perpendicular to the sun rays (1), observing if the shadow is parallel to the concentrator (2). Rotate the concentrator by spinning the entire system (3) to follow the sun.

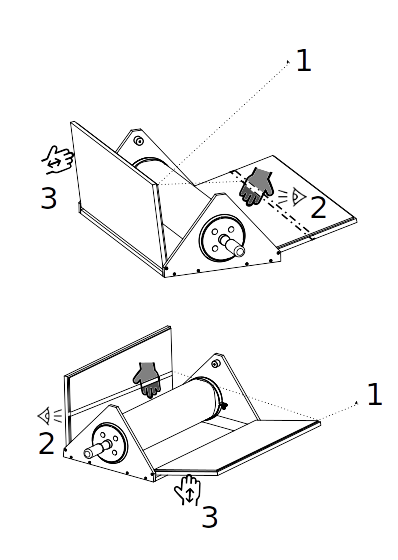

After orienting the azimuth, it is time to position the laterals and focus the direct sunlight rays (1) into the vacuum tube by using your hand to observe the light reflections (2) and adjusting the laterals (3).

HEATING TIME

The heating time will depend on various parameters: solar power, the type and quantity of material being heated, and proper concentrator orientation. Materials have a specific value representing the energy required to change their temperature. There is a factor of nearly 1000 between air and water.

TEMPERATURE

The temperature of the concentrator must be monitored by temperature sensors. One sensor measures the oven temperature, and the other measures the material's temperature. It's essential to analyze the values of both temperatures, observing whether the solar heat continues to warm the entire system or if the heat transfers from the concentrator to the material. When the material's temperature is higher than the concentrator's temperature, the system is already losing heat. It is crucial not to exceed 310°C to avoid breaking the glass tube.

MAINTENANCE

To maintain the concentrator's performance and safety, regularly measure and monitor the temperature to ensure it doesn't exceed 320°C to prevent vacuum tube degradation. Perform regular inspections and adjustments if necessary.

Please log in or sign up to comment.